The Importance of OEM Computer Assembly

Blog

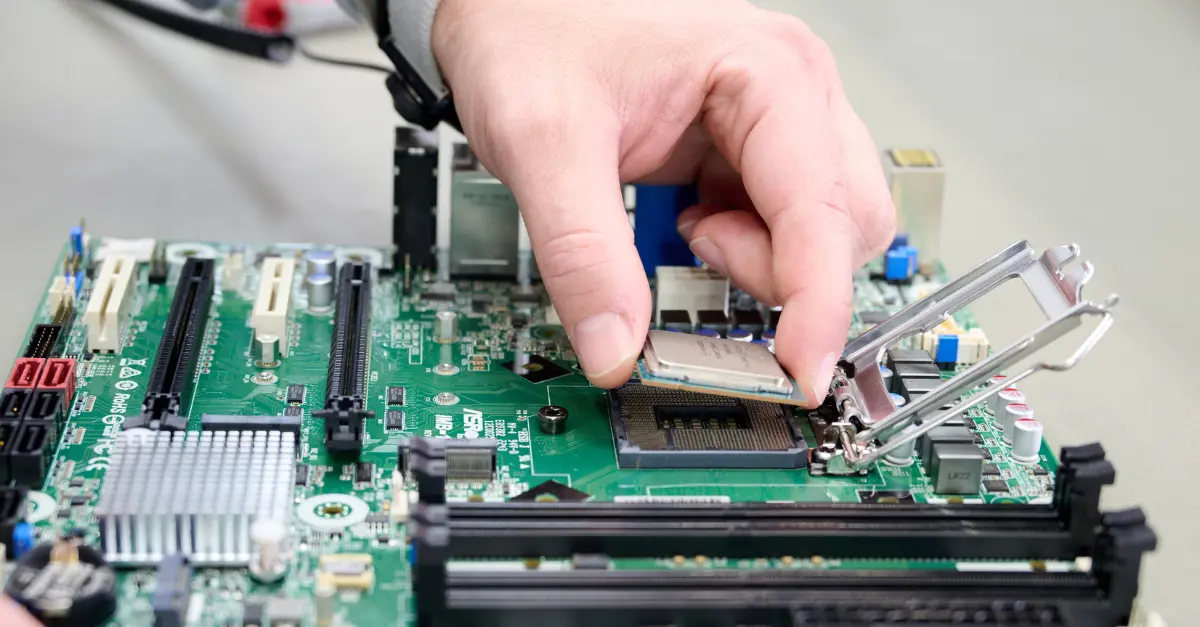

For a computer system to perform reliably and efficiently, quality assembly is essential. Even with the latest components, improper handling during assembly can shorten system lifespan and increase the risk of failure in the field. At New Era Electronics, we specialize in OEM computer assembly designed to meet exacting technical requirements and help customers reduce time-to-market. From improving consistency to freeing up engineering resources, OEM computer assembly delivers several critical advantages that directly impact product quality, delivery timelines, and customer satisfaction. This includes:

Reliability Through Consistent Assembly

Consistency in computer assembly reduces the margin for error. Without clear procedures, documentation, and skilled technicians, even small mistakes can result in significant field issues. We follow strict, repeatable processes in an ESD-safe environment to ensure each system meets the highest quality standards. This not only improves product reliability but also prevents costly product returns and disruptions.

Imaging and BIOS Configuration

System imaging is a vital but often overlooked part of OEM computer assembly. We use automation and image capture tools to streamline this process, allowing us to deploy multiple images quickly and accurately across high-volume orders. Whether it’s a single image across thousands of systems or several image versions with specific deployment rules, we ensure every unit ships fully prepared. BIOS configuration, custom settings, and branding can also be integrated at this stage, providing a complete and consistent out-of-box experience.

Testing to Prevent Field Failures

Our assembly process includes robust testing tailored to customer requirements. Whether it’s a basic power-on test or a full burn-in, testing reduces field failures. The importance of this increases with high-stakes applications where a system failure can mean downtime for an entire customer operation.

Certifications and BOM Adherence

We follow exact BOMs and manage long-lifecycle components to ensure consistency across every build. By managing and locking configurations, we help streamline the certification process for the end product.

Why New Era Electronics?

OEM computer assembly is just the beginning. Our services extend to:

- Component sourcing and lifecycle planning, including BOM freeze

- Supply chain management, including dropship and hold options

- Custom branding and labeling

- Documentation and revision control

These services are designed to reduce risk and protect your production timelines.

OEMs choose to partner with New Era Electronics because we bring technical depth, logistical support, and flexibility to every project. From initial configuration to final delivery, we take a solution-first approach, aligning with your business goals and simplifying your path to market.

Whether you need help scaling production, managing component obsolescence, or offloading the burden of OEM computer assembly, we’re here to help. See our full list of computer assembly, imaging, and testing services.